Mechanical Vibrations

Engineers understand mechanical vibrations. It is a phenomenon where significant forces induce significant motion of heavy objects. An unbalanced shaft on a rotating machine, for example, can induce large vibrations of a machine that weights hundreds of pounds. Such vibration can be easily detected just by touching the machine with a bare hand. Often machine vibration can be detected just by looking at the machine.

Acceleration due to vibration is usually measured by a piezoelectric accelerometer. It is a sensor where the acceleration of a vibrating object is imposed on a mass that is attached to a piezoelectric crystal. The inertial force needed to move the mass applies strain on the crystal and it generates charge proportional to the strain. The charge is converted to voltage and because inertial force is proportional to acceleration, the sensor outputs voltage that is proportional to the acceleration of the location where it is attached. Figure 1 is a schematic diagram of a piezoelectric accelerometer.

Figure 1 Piezoelectric Accelerometer

Stress Waves

Stress waves are not mechanical vibrations. Stress wave is a microscopic phenomenon that does not involve mass in motion. It is an extremely small stress disturbance that travels through elastic materials at the speed of sound. In hard metals, this speed is in the 16,000 fps to 20,000 fps range. Being a microscopic phenomenon, stress waves do no affect the operation of machines as they travel through them. They cannot be felt by touching a machine or detected by looking at it.

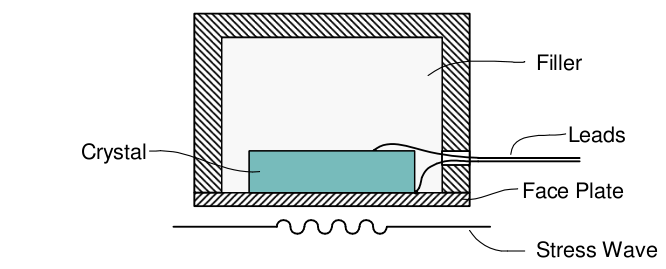

Stress waves are a microscopic phenomenon and, therefore, are excited even by extremely low forces. Any two contacting objects that slide relative to each other generate stress waves. For example, sliding a finger on the surface of a large machine induces stress waves that can be measured by a sensor located far from the contact location. Stress waves can be detected and measured with a piezoelectric stress-wave sensor. Figure 2 is a schematic diagram of such sensor.

Figure 2 Stress Wave Sensor

Stress waves traveling on the surface of a machine are applied directly to a piezoelectric crystal. The crystal undergoes strain and generates charge proportional to it that is then converted to voltage. Filler is used to prevent motion of the crystal due to vibration, making it insensitive to acceleration.

Using Stress Waves for Monitoring of Fuel Injectors

When the pintle of a fuel injector reaches the end of its stroke upon opening or closing the injector nozzle, it impacts the body of the injector and generates a stress wave. This stress wave travels through the body of the injector and through the engine and can be measured by a stress-wave sensor that is located far from the injector. The intensity and shape of the stress wave can be compared to a standard or signatures of different injectors can be compared to each other to identify a failing injector.